Our sustainability report is now live and free to download!

What is a CO2e receipt and how is it measured?

What is a CO2e receipt and how is it measured?

Sustainability

At Oxwash, we measure our Greenhouse Gas emissions across our operations. CO2 (Carbon dioxide) isn’t the only emission that needs to be looked at, but for simplicity, we have done as recommended by the Kyoto Protocol and converted all emissions to CO2e or ‘equivalent’. GHG emissions are divided into different scopes depending on how ‘direct’ they are - scope 1, 2 and 3.

To calculate our yearly emissions, we keep an inventory of how much electricity and gas we use and then multiply these with the official conversion factors which gives us the kilograms of CO2e emitted. To calculate the CO2e emitted per kilogram washed, we look at how many kgs of items we have washed a certain week, compared to how much energy used that week. This means that the figure is dynamic - some weeks we use more energy than others, for example, we receive lower volumes and have to run the machines when they are not full. For now, we have settled for an average CO2e per kg based on the energy used and the kg washed in 2021, but this figure will be updated regularly.

How do we know how much we saved?

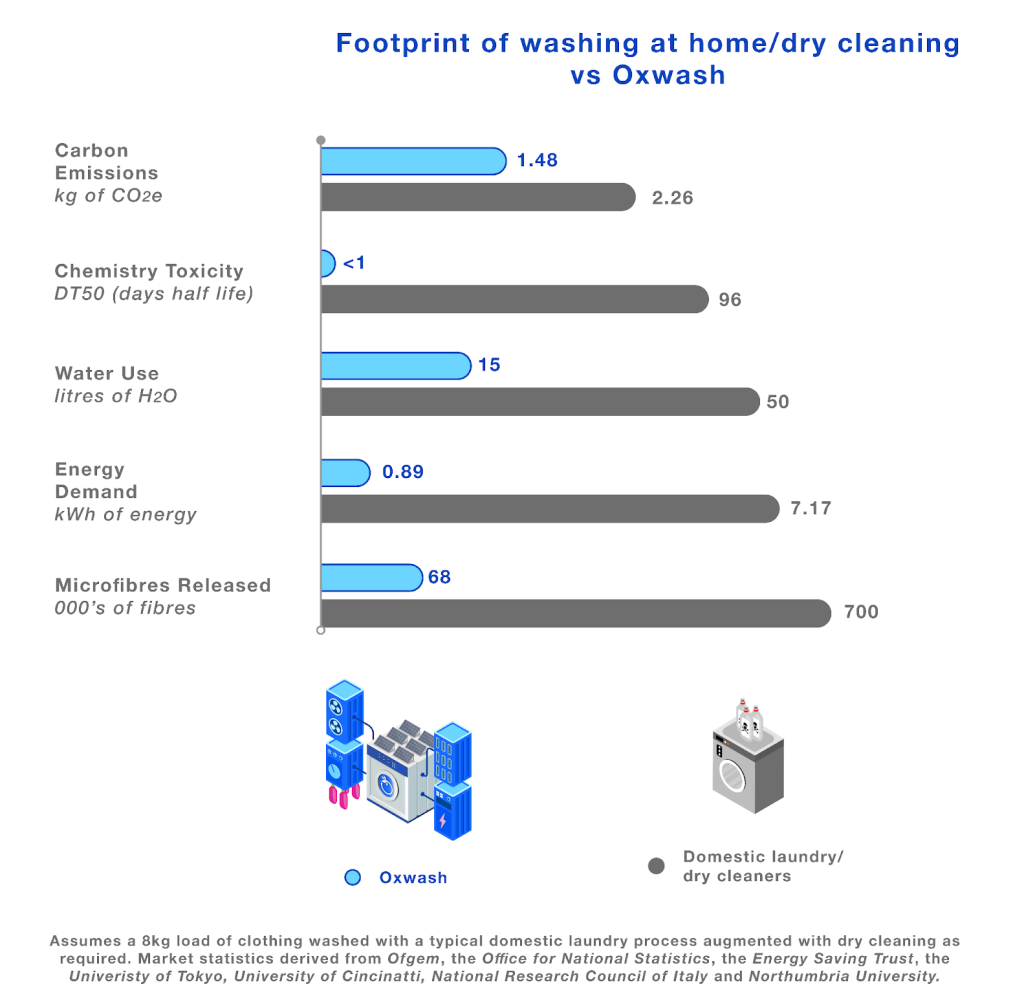

Well, we know how much energy the industry generally uses through both peer-reviewed academic research and reports from the European Union. To get an accurate number, we have plugged those numbers into our model, and calculated how much CO2e that Oxwash would use “if it was an average company in the laundry industry”. It means that we have taken our volumes but instead of using our actual energy usage, we have added the industry average. In addition, we have added the CO2e emissions of delivering by 3.5t diesel van (standard for the industry) as our first model includes the electricity used to charge our electric cargo bikes and electric vans.

This way we have two detailed and accurate numbers - firstly, our actual emissions and secondly, our theoretical emissions would have been a standard laundry and dry cleaning service. The amount of CO2e saved is the difference between these two.

What’s next?

We want this model to be even more detailed and accurate, which is why we have installed energy sensors on each of our machines. Using these energy readers we will be able to say, not only how much CO2e that has been used per kg, but also how the washing of different materials and types of garments result in different CO2e emissions per kg. At the moment, we only have one measurement for a dress - but a simple, non-iron dress will require less energy than for example a ruffled dress, which takes a long time to iron and therefore results in a higher CO2e emission. We are working hard to improve this model in 2022, but in the meantime, we are proud and confident to have an accurate way to measure our CO2e savings.

In numbers:

For a 12 kg process at Oxwash we use 21.77 kWh of energy and 4.39 kgs of CO2e. This is about the same amount of CO2 that it takes to drive 22 miles in a small car. For reference, only 1 kilo of beef meat results in the emission of 70 kg of CO2e which is equivalent to a 350 mile petrol car ride! The average industry figure for a 12kg wash is 29.40 kWh of energy and 6.39kgs of CO2e, resulting in a saving of 2 kgs of CO2e per 12 kg wash. Oxwash uses 31.3% less CO2e and 25.9% less energy than the industry average.

Related Articles

B Corp™ certified.

Surpassing NHS-grade disinfection.